eJuice & Small Vial Bottle Labeling Methods

(or ‘How do I label my ejuice and eliquid bottles?’)

I recently found out that there is no mechanism in place to support the eJuice industry in it’s manufacturing and packaging endeavors. Not too much out there about bottle labeling techniques either. I found eJuice suppliers by the dozen. I found bottles and containers to hold the eLiquid. I found folks that print sheets of label material to be applied by hand. What I didn’t find was any kind of information on running an efficient operation when it comes to the production, bottling, labeling and packaging of eJuice and supporting product. This page is being created to help educate people on the various options regarding how to label and package your eJuice and eLiquid products. Keep an eye out for more on bottle filling, capping and alternative packaging method posts.

What Types of Containers?

Were going to be talking about eJuice and eLiquid containers in this guide, but the ideas here can be applied to anything that you need a label on. Bags, boxes and bottles of all shapes and sizes can labeled with relative ease as long as you have a basic understanding of some of the concepts.

Getting Your Labels Printed

You have two options; either print them yourself with your own printer or have them printed for you. The format is in sheets or rolls. For printing at home you have a few choices. The first option is that you can use a standard inkjet or laser printer, either in color or black and white. The models vary and each has its own set of benefits and drawbacks. You can start out with an inexpensive inkjet printer and work your way up to an industrial color laser printer that was designed exclusively to print small labels. The dollar range you’re looking at is $50 to $5000. One thing to consider is the cost of ink for each particular printer. More than once I’ve gotten burned after getting a great deal on a printer, only to find out that the ink toner cartridges cost more than the printer itself. To have a print shop print your labels you’ll need some information for them. For sheets it’s just a matter of letting them know the size, shape and colors of your label. For roll labels you’ll need to know what orientation your labels will need to be on the roll as well as letting them know what the biggest roll you can accept is. The second option is that you get a more specialized printer called a thermal printer. These are nice because they don’t use any ink at all, and instead use heat to make an impression on the labels are they pass the printer head. The downside is that they are limited exclusively to black and white printing. None-the-less, it’s an inexpensive option to get your operation started.

Types of Labeling

• Labeling By Hand

Labeling by hand is by far the least expensive way to get started. If you have low volume or very small run numbers, then labeling your eJuice bottles by hand is the way to go. That being said, the cost can escalate if your volume increases. There are more efficient and less expensive ways to label once you start doing more business. Labeling your containers by hand keeps the startup costs limited to the labor it takes to have someone (or yourself) apply labels, the cost of printing the labels and the skin on your fingertips. The labels are individually pulled from the label backing and hand applied to the container. I can tell you from experience, that the skin on your fingertips takes a serious beating if you start to have any kind of large numbers. A couple hundred labels and you’ll wish you had rubber gloves or a label applicator.

Something to consider when labeling your containers this way is that the consistency is not always the best. It’s harder than you’d think to get the same size label on the same size container exactly the same way, every time. If you’re mailing one’s and two’s it’s not a big deal, but if you have them on a display shelf or other sales venue any discrepancies look really bad. At best you’re looking at being able to label around 300 to 500 labels an hour with this method. Pros: least expensive labeling method for smaller quantities, able to do small specialized batches. Cons: labor starts to get expensive when you have a larger volume, inconsistent application, slow labeling speed.

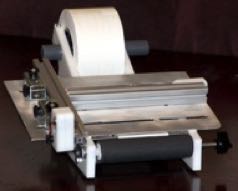

• Manual Labeling & Semi-Automatic Labeling

Manual and Semi-Automatic labeling are very similar. It means that you’re using a machine to assist in the labeling in order to speed up the labeling process as well as get some consistency in the label application itself. The difference between the two is that one has a motor and one doesn’t. In both cases the customer has to place the container on the labeler and either press a foot pedal to start the labeling process or drag the container over the labeler. Most labelers are specialized so that they’re restricted to labeling one kind of item. That being said, there are a few that are versatile enough to switch container types on the fly with little setup time. The cost on these types of machines vary widely. Semi-Automatic labelers usually run from $1000 to $5000 depending on the model. Manual labelers can run from $500 to $2500. Our label applicator for example is a manual labeler that will run you $449 to $649 depending on the model and is on the faster end of the labeling speeds available. Generally the labeling speeds that you can achieve using these types of labelers range from 500 labels an hour up to 1200 labels an hour. The application speed depends on three things; operator proficiency, the speed of the motor (if it’s semi-automatic) and the type of label application you’re doing. With a good labeler you should be able to get around 1200 - 1800 of the small diameter containers used for eJuice labeled in an hour. Be sure to check the speed claims by some of the label manufacturers as the speeds are sometimes exaggerated. Ask for videos showing that speed on a similar container style to yours. 5 ml, 10 ml, 15 ml and 30 ml bottles should all be easily labeled by the same bottle labeler with no need for long setup times and adjustments. Pros: consistent label application, relatively inexpensive, can be used in an array to boost the containers labeled an hour, easily replaceable if the labeler breaks down. Cons: operator training, electronic label sensors have trouble sensing when clear labels start and stop, be wary of label applicators charging more for ‘brand’ than efficiency.

• Fully Automated

These are the behemoths of the labeling world and can easily start out at $15000 on up to a couple hundred thousand.

These are of course what we all aspire to have in our shop. They can usually label in speeds ranging from 100 to 1000 labels a minute. They do usually require a dedicated highly trained technician in order to run and setup. Pros: very fast, very consistent. Cons: very expensive, requires a lot of training, long downtime if breakage occurs.

The Bottom Line

Before you order a labeling machine, be sure to find out what all the costs will be. There could be hidden costs that could add substantially to your time or cost involved. Ask the sales rep about hidden costs and see if they’re willing to help you with all aspects of your project. We are happy to help walk you through every step of your new labeling project.

Give us a call and see how we can help!

800-617-5251

$499 • Zap Labeler

Crazy Fast 1800+ Bottles Per Hour!